Search

|

|

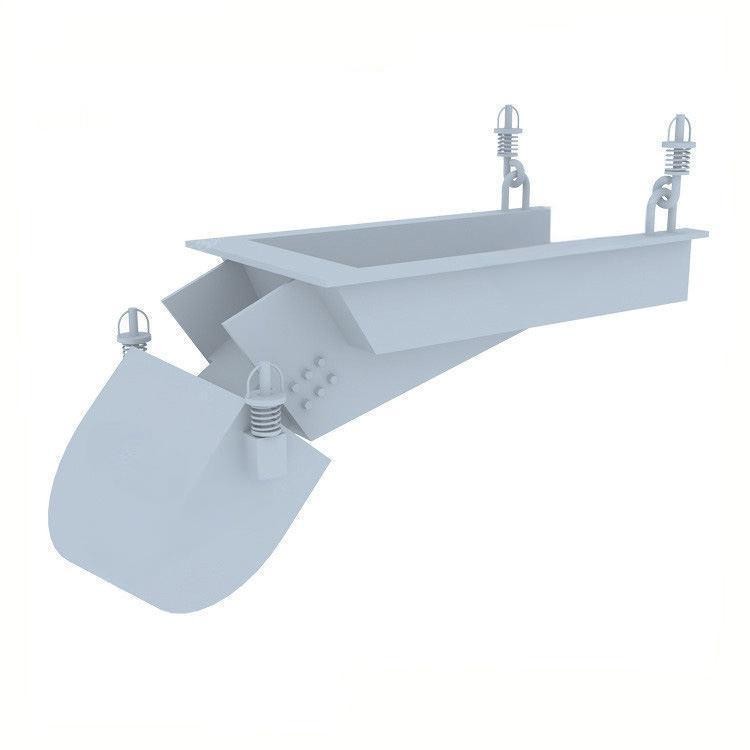

Product Performance and Core Advantages

1. Compact size, lightweight, simple structure, easy installation, easy maintenance, low operating cost;

2. Utilises mechanical vibration principle, low energy consumption;

3. Adjustable volume to change flow rate anytime;

4. Centralised and automatic control of the production process;

5. Minimal wear of the feeding hopper;

6. The eccentric block is the vibration source, low noise, low power consumption, good adjustment performance, with no material spillage.

Product Applications

This electromagnetic vibration feeder, as a general-purpose material conveying device, is widely used in the following industries and scenarios:

1. Mining: for transporting and batching ores and crushed stones, suitable for feeding crushers and screening machines;

2. Building Materials Industry: quantitative conveyance of cement, sand, stone, and tile raw materials, catering to batching plants and production line requirements;

3. metallurgy Industry: transportation of ores and auxiliary materials in steel mills and non-ferrous metal smelting;

4. Other Scenarios: material transfer and quantitative feeding in coal, power, glass, ceramics, and other industries.

After-sales Service

1. Warranty Commitment

Global unified warranty: 1 year for the whole machine, 2 years for core parts. Within the warranty period, free repair services and replacement of faulty parts are provided, shipping cost borne by the buyer.

2. Multilingual Technical Support

Provides 24/7 online technical consultation, supporting English, Spanish, German, French, Russian, Japanese, Korean, and other major languages.

Support channels: professional technical team responds within 4 hours via email, WhatsApp, WeChat, or video calls to solve equipment operation issues.

Free multilingual operation manuals, installation videos, and maintenance guides (PDF / video format) are provided.

3. Spare Parts Supply

Establishment of global spare parts warehouses (located in Germany, USA, Singapore, China) to ensure fast delivery.

Long-term supply of original factory parts, bulk orders enjoy discounted prices, and lifetime supply service is guaranteed.

4. Customised After-sales Plan

Provides personalised maintenance plans based on customers' production schedule and usage frequency.

Regular remote follow-ups: quarterly tracking via video or email, monitoring equipment operation, providing maintenance advice, and collecting feedback.

Packaging and Transportation

1. Packaging Standards

The equipment main body is packed in export-grade plywood crates, internally lined with shockproof foam and moisture-proof film to prevent collision and moisture damage during transportation;

External packaging clearly marked with equipment model, specifications, weight, transport orientation, etc., for easy verification by customers upon receipt.

2. Transportation Methods

International transportation: sea or air shipping available based on customer requirements, assistance with customs declaration and clearance;

Transport protection: transportation insurance provided, with compensation by the insurance company in case of damage during transit, ensuring customer rights.

3. Receipt Instructions

Customers should check the equipment model, quantity, and accessories upon receipt, and inspect the packaging. Contact us immediately if any issues are found;

Reasonable damage occurring during transport will be covered by free repair or replacement services.

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories