Search

|

|

Product Overview

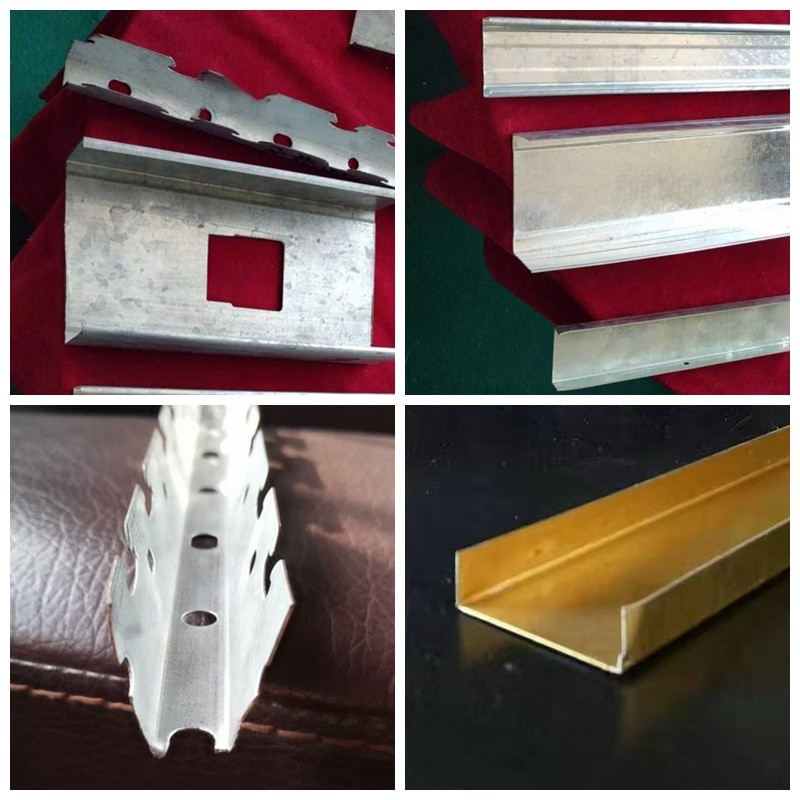

This customized light steel keel forming machine is a high-efficiency production equipment specially designed for the architectural decoration industry. It integrates core functions such as cold bending forming, continuous processing and precise cutting, enabling the integrated forming of main keels (load-bearing keels), secondary keels (sheathing/cross keels) and various decorative suspended ceiling keels. Adopting industry-standard light steel processing technology, the equipment is suitable for raw materials like cold-rolled steel plates and galvanized steel plates with a thickness of 0.5-1.2mm. With high forming accuracy and strong stability, it serves as a core production device for ceiling projects, interior decoration and industrial decoration projects.

Core Advantages

Customized Production Capacity: It supports customization of keel specifications (width, height, wall thickness), forming dies (U-type, C-type, T-type, L-type, etc.) and production speed (adjustable from 0 to 15m/min) according to customer needs. It perfectly meets the personalized production requirements of different ceiling structures and load demands, solving the problem of non-standard keel processing.

Efficient Cold Bending Forming Technology: Adopting numerical control cold bending forming technology, it requires no high-temperature heating, thus maintaining the original mechanical properties of steel. The formed surface is smooth without damage, and the dimensional error is ≤±0.3mm. The integrated production line covers processes including material uncoiling, leveling, punching, forming and cutting, with high automation. The single-shift output can reach 3,000-5,000 meters, greatly improving production efficiency.

Integrated Processing of Main and Secondary Keels: One machine is suitable for the simultaneous production of main keels (load-bearing core) and secondary keels (auxiliary fixing). The keels feature high connection accuracy and fit closely during installation, which effectively improves the flatness and firmness of ceiling projects and reduces construction losses.Customizable English Translation of Product Manual (Sample framework)

Stable and Reliable Structural Design: The machine body is made of thickened steel plates through welding, with high rigidity and good shock resistance. Key transmission components are made of high-quality alloy steel, matched with precision bearings and frequency conversion speed control system. It has low operating noise (≤75dB) and a long service life (≥8 years under normal maintenance).

Safe and Convenient Operation Experience: It is equipped with an intelligent touch operation console, which displays production parameters (speed, length, output) in real time and supports functions such as fixed-length cutting, automatic counting and fault alarm. Safety devices such as guardrails and emergency stop buttons are complete, complying with industrial safety standards, enabling even novice operators to get started quickly.

After-sales Service

1-year warranty, 24/7 online technical support, free installation guidance and operation training, and lifelong spare parts supply.

Packaging Instructions

Wrapped with moisture-proof film + reinforced wooden case packaging, with built-in shock-absorbing buffer materials, complying with international transportation packaging standards.

Logistics & Transportation

Cooperate with professional freight forwarders, offering optional sea freight/air freight, full-process cargo tracking, assistance in handling customs clearance documents, and ensuring on-time delivery.

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories