Search

|

|

1. Basic Equipment Information

The model is 800/2S, which is a large-scale industrial-grade double-chamber vacuum packaging machine. Its core structure consists of a flatbed worktable and an automatic swing-arm mechanism, mainly used for packaging products such as fresh/frozen beef and mutton, cut beef and mutton, and seasoned beef and mutton.

2. Core Configuration and Technical Parameters

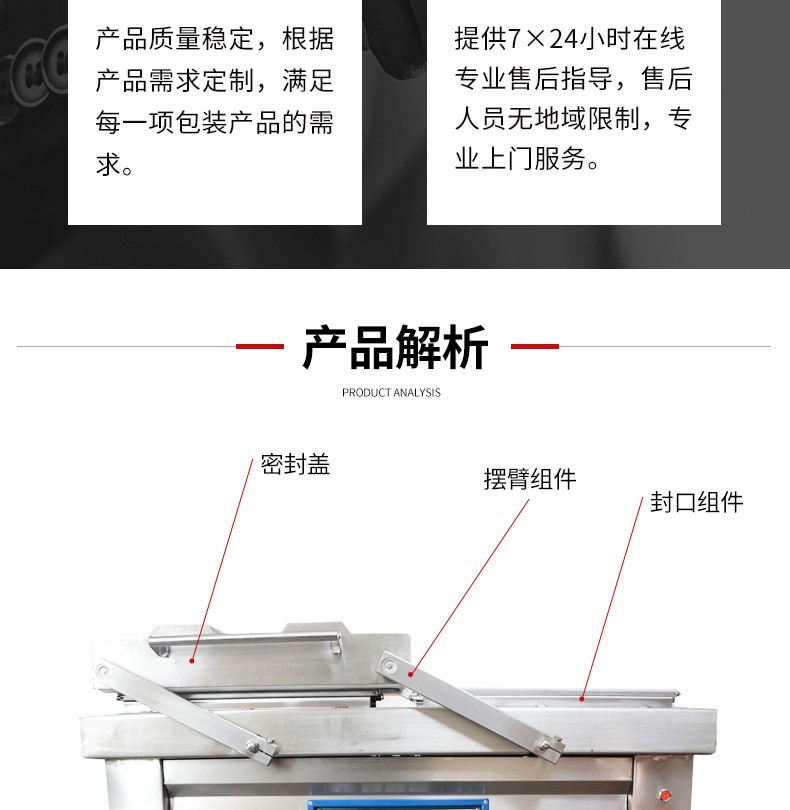

In terms of the vacuum system, the vacuum pump power is ≥4.0KW (with an optional 6.0KW enhanced version), the ultimate vacuum degree is ≤-0.098MPa, the vacuum chamber size is 800mm×600mm×300mm, and the two chambers can work alternately to achieve continuous operation. The worktable and swing-arm mechanism adopt a 304 stainless steel flatbed, which is corrosion-resistant and easy to clean. The swing arm is automatically controlled by PLC, with an adjustable angle of 0-90°, and the load capacity for a single packaging is ≤50KG. The sealing strip is made of high-temperature-resistant silica gel, with a service life of ≥8000 times, and the sealing width can be adjusted from 10mm to 15mm. In terms of automatic operation, it supports touch screen human-computer interaction, with three modes: manual, automatic and semi-automatic. The packaging cycle is 20-40 seconds per time, the swing-arm response speed is 0.3-0.5 seconds per time, and the positioning error is ≤±2mm. In case of faults such as abnormal vacuum degree and excessive temperature, it will automatically alarm and display troubleshooting guidelines. Other parameters include a 380V/50Hz three-phase five-wire power supply, an equipment weight of approximately 800KG, an overall dimension of 2200mm×1500mm×1800mm, and an IP54 protection level.

3. Core Advantages for Beef and Mutton Packaging

It has an outstanding fresh-keeping effect. The high vacuum degree can quickly remove air and inhibit bacterial growth. The shelf life of fresh products is 15-30 days at room temperature and 6-12 months in freezing, which is 3-5 times that of ordinary packaging. It can also prevent fat oxidation and moisture loss. It has strong adaptability: the flatbed worktable is compatible with vacuum bags of sizes ranging from 100mm×150mm to 600mm×800mm; the automatic swing arm reduces manual contact; and the independent control of the two chambers can meet the different vacuum requirements of fresh and frozen beef and mutton. It has stable industrial-grade production capacity: it can produce 800-1200 pieces per 8-hour shift; the 304 stainless steel body can work continuously for 24 hours, with a failure rate of ≤0.5% per year; and the adjustable sealing temperature of 100-180℃ balances nutrient protection and sealing firmness.

4. Application Scenarios and Supporting Suggestions

It is suitable for large and medium-sized beef and mutton slaughtering and processing plants, cold chain food enterprises, and catering chain enterprises, and can be used for bulk packaging, finished product packaging, and food material pre-processing packaging. It can be optionally equipped with automatic feeding and bag supply machines to upgrade the production line. It is recommended to match it with food-grade nylon composite vacuum bags with a thickness of ≥0.08mm, and it can also be matched with cold chain storage equipment to form an integrated fresh-keeping solution.

5. Summary of Equipment Features

With the highlights of "high vacuum, high automation, and high stability", it balances efficiency and quality, meets food hygiene standards, and is suitable for various beef and mutton products. It is an ideal equipment for large-scale and standardized packaging in the meat processing industry.

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories