Harbin Dongjin Hisense Technology Co., Ltd.

The company's main business is the research and development, design, production, sales and domestic, Foreign agricultural planting, operation and sales of agricultural products and agricultural machinery import and export business. The company's main products It is a self-propelled corn combine harvester, a self-propelled corn kernel combine harvester, a semi-tractor horse Potato Harvester, Self-Propelled Silage Harvester, High Horsepower Tractor and Organic Non-GMO Soybeans, silage and other crops.

|

|

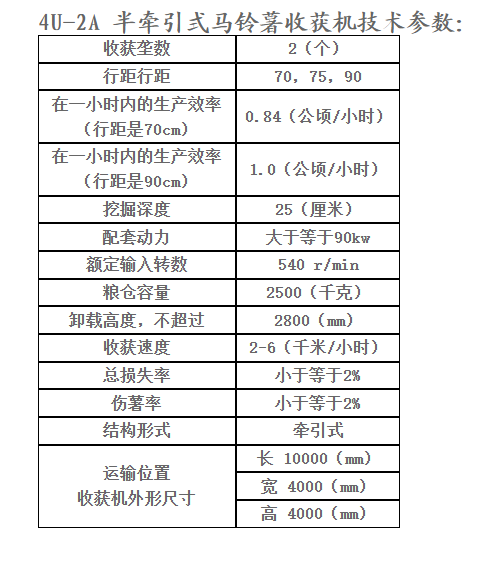

Features of 4U-2A Semi-trailed Potato Harvester:

1. The 4U-2A potato harvester is equipped with a potato collection box and a platform for picking up impurities. The operating conditions of the harvester are that the horizontal slope of the operating land should not be greater than 4 degrees, and the potato planting area with light or medium soil in temperate climates (except mountainous areas);

2. The impurity pick-up personnel platform designed by 4U-2A can accommodate 4 personnel to work at the same time;

3. The 4U-2A potato harvester needs to be pulled by a wheeled tractor, and the harvesting row spacing is 70, 75 and 90cm;

4. The efficient production efficiency of 4U-2A potato harvester is more in line with the needs of modern large-scale planting and agricultural development;

5. The vibration frequency and amplitude of the oscillator can be adjusted flexibly, and the crushing force of the rollers on the clods, the extrusion force and the front separation shock escort chain can be adjusted, which can improve the degree of separation of potato soil and the degree of crushing of clods on the ridge. It is beneficial to harvesting; the angle of the digging shovel is adjustable, and the height of the roller is adjusted by the support screw; the connecting rod of the rear separation conveyor chain is completely wrapped in rubber, which completely avoids the damage caused by the vibration during the conveying process of the potato; the impurity removal conveyor chain is installed in the rear The top of the separation conveyor chain is used to separate the stems and leaves and return them to the field; the upper and lower cleaning separators with adjustable inclination angle are used to separate small debris; the stepless speed regulation oscillator conveyor chain and separator guarantee for efficient harvesting and effective impurity separation;

6. The use of table sets and conveyor separation shock chains (inclined cleaners) produced by the world-class manufacturer WEIMAR (Germany), conveyor chain belts and locking mechanisms produced by ARTEMIS, and advanced European hydraulic devices greatly improve the performance. Reliability and service life of the harvester;

7. This harvester has the characteristics of high harvesting efficiency, no skin damage, low skin breaking rate, smooth operation, no clogging of stems and leaves weeds, good soil breaking function, simple structure and long service life. The most important thing is that the agricultural film in the soil can be directly removed and separated on the ground, without affecting the planting and growth of crops in the next year;

8. Adopting international advanced technology, all racks and chain drive wheels adopt the casting process, which reduces the wear of racks and chains and prolongs the service life.

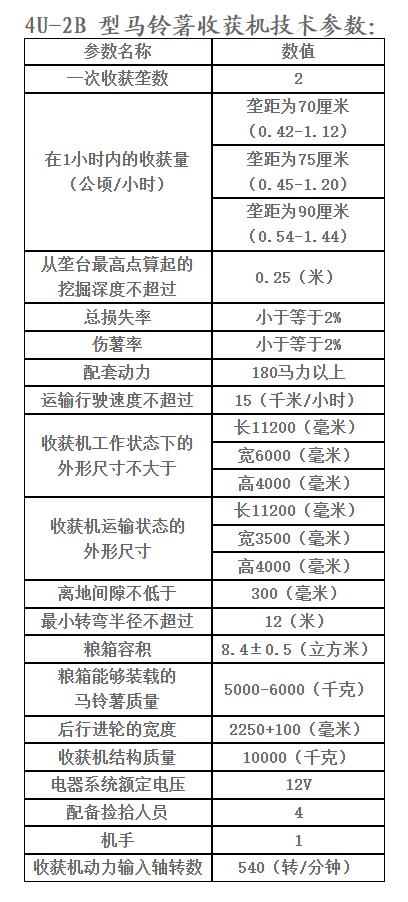

Features of 4U-2B Potato Harvester:

1. The two-row side-traction potato harvester with grain tank is specially designed for large-area potato harvesting. The ease of operation, adjustment and maintenance enables this machine to be used in a variety of difficult terrains;

2. It is specially designed for clay soil, suitable for clay harvesting, and can complete soil crushing, digging, impurity separation, cleaning and potato collection at one time. High harvesting efficiency, adjustable ridge spacing, large-capacity grain tank, and reasonable unloading height, to meet customer transportation needs, and can cooperate with screening machines for warehousing or processing production line one-stop operation;

3. The lateral adjustment of the oil cylinder can ensure the alignment of the harvester's excavation shovel and the ridge, and avoid the phenomenon that the excavation shovel and the ridge surface deviate during the harvesting process, resulting in missed digging and potato damage;

4. The center of gravity adjustment cylinder effectively ensures that when the vehicle is unloading potatoes, the center of gravity of the vehicle is in a reasonable position, preventing the vehicle from rolling, and further improving the safety and stability of the vehicle;

5. Side traction avoids tractor tires from pressing ridges, and the bottom of the grain tank is paved with scraped canvas to reduce potato damage: the special rubber raised conveyor belt reduces damage and removes the soil on the potato surface;

6. The clear and clear operation panel and electronic display system allow customers to easily control and complete the entire harvesting process: the efficient and stable hydraulic system provides a strong guarantee for the removal and transportation of the harvester;

7. The harvester is equipped with a starting brake system, which improves the safety of the vehicle. The rear wheel of the vehicle can realize hydraulic steering to reduce the turning radius and ensure that the vehicle can turn freely in a limited space;

8. The multi-layer baffle design and the mesh conveyor belt realize the separation of the stems and leaves of the potato, and the adjustable hydraulic shaking system can be adjusted according to the amount of soil, making the screening more thorough;

9. The electric inductive position sensor can sense the height position of the potatoes in the grain tank in real time, and make follow-up adjustments to the foldable part of the conveying device at the end of the grain tank in real time, which can effectively reduce the unloading height of the potatoes into the grain tank while the maximum Chemically reduces damage to potatoes. Compared with the contact induction device, a lot of manual operations are saved;

10. The roller type blocking cleaning device can clean the potato surface while preventing the potato from being lost: the floating disc cutter can effectively cut off the weeds without clogging or dragging the soil to reduce the digging resistance.

Instant Messaging

Instant Messaging Video Call

Video Call