Search

|

|

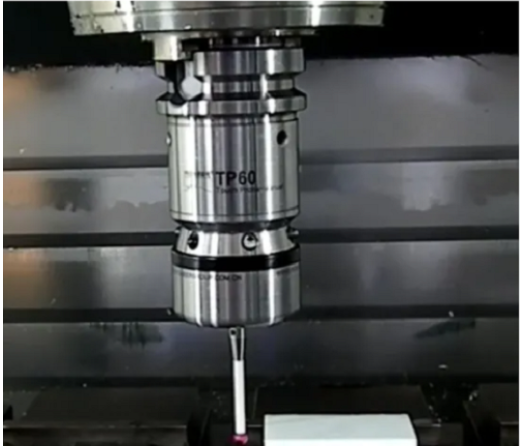

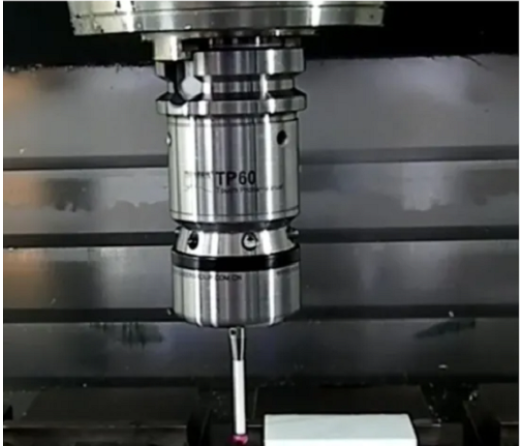

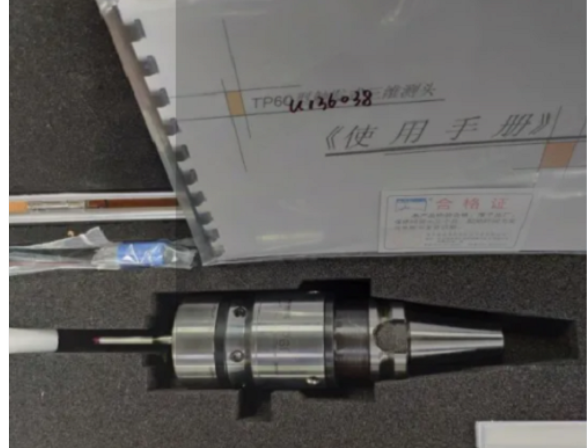

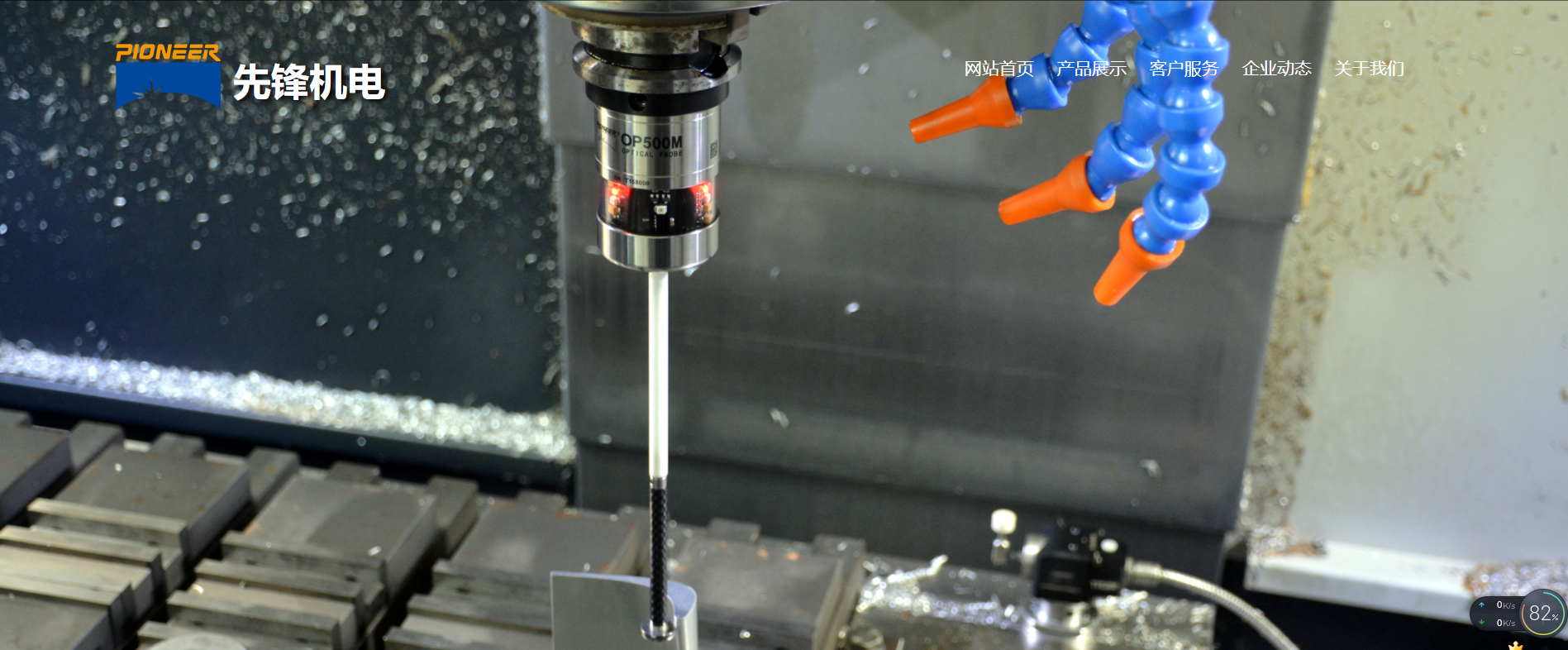

Composition of Probe:

TP60 trigger probe consists of three pieces:

1)The main part of TP60 trigger probe (including battery cabin ) ;

2)The 7:24 taper shank with standard of BT or ISO(the specification is optional )

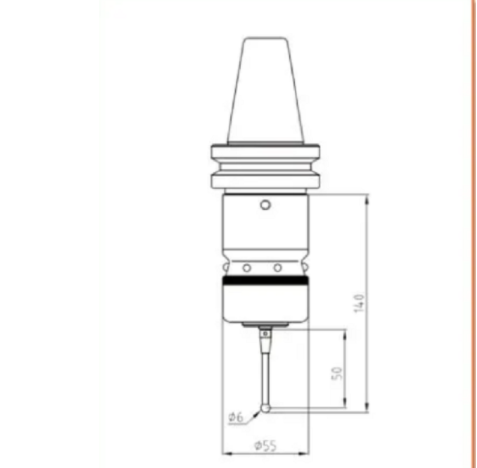

3)Stylus(standard model:M4-P50-RB6-S36).

Technical Parameters:

Stylus sensing direction: ±X, ±Y, +Z;

Stylus sensing over-travel : X-Y±15°, Z +5 mm;

The trigger force in Z direction: 1000 g;

Trigger force in X-Y surface( standard stylus ) : 65 -130g;

Unidirectional repeatability(2σ): ≤ 2 μm;

Input voltage is 24±10% V DC and output load current is 50 mA.

Seal grade: IP68.

Technical Characteristics:

Coaxial adjustment function of probe and shank: By adjusting the connecting link between the main body of the probe and the taper shank, coaxiality about the center of the measuring ball on the stylus and the center line of the taper shank can be adjusted (the factory precision: ≤5 μm);

Six LED indicator lights are used to show the trigger state of the probe.

Basic configuration:

The standard: M4-P50-RB6-S36;

Usually, the probe shank is 7:24 taper shank with the BT or ISO standards (the specification is optional );

A battery, model: CR2, 3.0 V, 800 mAh.

Applicable equipment and working condition:

Suitable for various specifications of machine centers, CNC boring and milling machines, and drilling-tapping machine centers, etc;

Suitable for checking work pieces of all kinds of solid materials.

Application:

Setting work-piece coordinate system and machining zero points manually before processing;

Detect and control the key dimensions, position coordinates and their precision manually between two processes;

Detect precision of the key dimensions, shapes, position after processing.

Ouch Probe for Machine Tool , Composition of Probe , Notes for Purchase

China Ouch Probe for Machine Tool , China Composition of Probe , China Notes for Purchase

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories