Search

- No link

|

|

Dry Batch Concrete Cement Mixing Plant Near Me

Product description

This fixed concrete mixer plant is stable in performance, accurate in weighing, with high productivity and good quality;

This fixed concrete mixer plant is stable in performance, accurate in weighing, with high productivity and good quality;

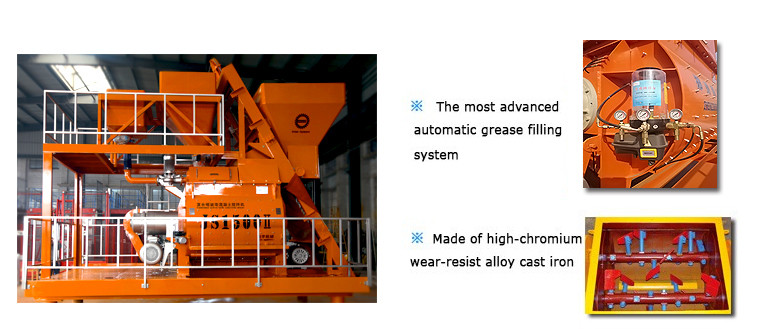

The mixing mainframe adopts decelerator and oil sealing system specifically designed and produced by foreign standard manufacturers for double-horizontal axle compulsive mixer.

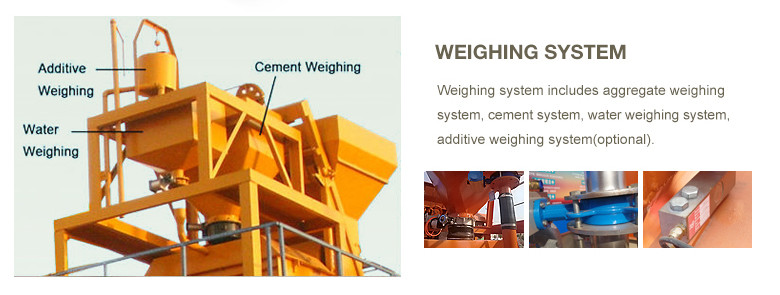

Each balance of the weighing system is equipped with three high precision cantilever weighing sensors..

The control system applies industrial controlled computer and electronic scale, with high measurement precision.

High Quality and Precise Concrete Production (with Fully Automatic Computerized Control System).

The whole machine is controlled by computer which makes operation easy.

The main electric components are from famous brand.

This fixed concrete mixer plant is stable in performance, accurate in weighing, with high productivity and good quality;

Features of Hopper Lift Concrete Mixing Plant

1. HZS35 concrete mixing plant adopts JS750 twin shaft horizontal concrete mixer with superior efficiency and high energy-saving.

2. The electronic weighting system of HZS35 concrete batching plant has a buffer device and automatic volume compensation with high accuracy.

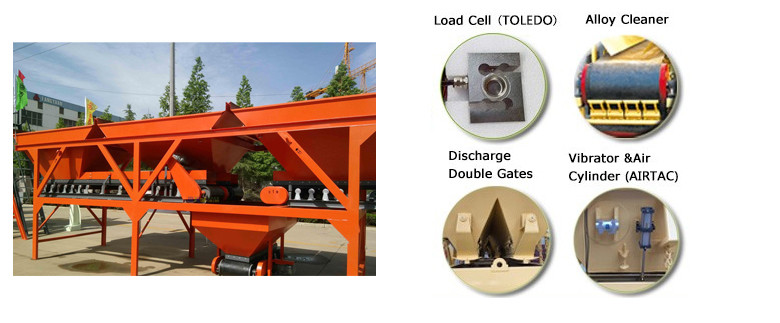

3. Sand & gravel batching machine use PLD1200 with has highly accuracy measuring.

4. Equipped with maintenance walkway, engineer can examine HZS35 stationary concrete mixing plant timely and easily.

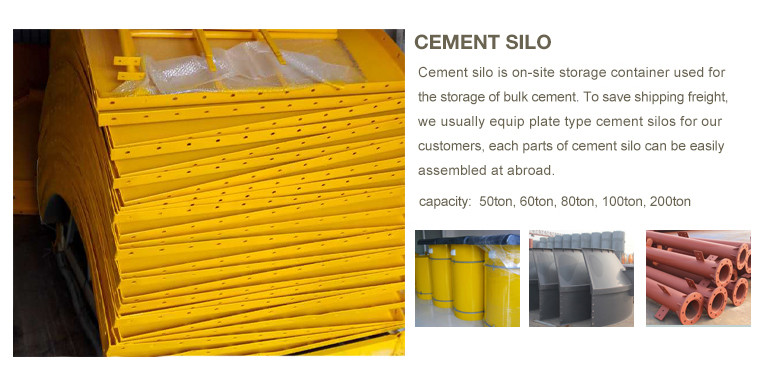

5. Cement is stored in cement silo and delivered by concrete screw conveyor.

6. Water supply system is composed by water tank, water pump and water weigh.

HZS35 concrete batching plant is operated by PLC fully automatic control system. All the mixing and batching systems run automatically.

Technical Parameters of Lifting Hopper Concrete Mixing Plant

| Model | HZS25 | HZS35 | HZS50 | HZS75 |

| Capacity | 25m3/h | 35m3/h | 50m3/h | 75m3/h |

| Mixing system | Twin shaft concrete mixer | |||

| Aggregate feeder | Bucket (Skip hopper) | |||

| Discharging height | 1500-3800mm | 3800mm | 3800mm | 3800mm |

| After-sale service | Erection & commissioning, operator training | |||

| Warranty | 12 months after erection | |||

| Concrete mixer | JS500 | JS750 | JS1000 | JS1500 |

| Discharging volume | 500L | 750L | 1000L | 1500L |

| Charging volume | 800L | 1200L | 1600L | 2400L |

| Mixing circle | 72s | |||

| Max. mixing size | 80/60mm | |||

| Aggregate batching machine | PLD800 | PLD1200 | PLD1600 | PLD2400 |

| Storage bins quantity | 2 or 3 or 4 sorts | 3 or 4 sorts | 3 or 4 sorts | 3 or 4 sorts |

| Aggregate scale hopper | 800L | 1200L | 1600L | 2400L |

| Weighing system | Water, Cement, Additive | |||

| Weighing precision | ±1% | |||

| Air system | Air compressor, etc | |||

| Control system type | Computer auto-control module (PLC can be optional item) | |||

Packaging&Shipping of Our Products

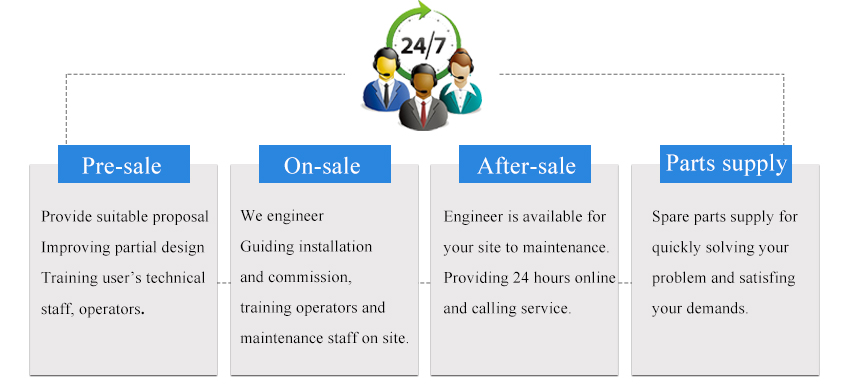

Our Service

1.According to your inquiry, the first time to give the offer, the first time to give production.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts of concrete mixer plant as soon as possible when necessary, equipment repair parts provided by the seller are original, authentic, quality goods.

Company Information

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crusher,crushing and screening production line,excavator,bullsozer,loader,dump truck,truck crane,concrete mixer truck and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have received the ISO9001,CE,SGS etc certificates.Our equipment has exported to 35 countries,including:Russia,India,Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant or constructions machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

FAQ

DO YOU SELL WET OR DRY ConCRETE BATCHING PLANTS, STATIonARY OR MOBILE?

Yes, we can offer both wet and dry concrete batching plants, and stationary type and mobile type are both available.

I NEED ADVICE ON THE CORRECT EQUIPMENT TO USE, CAN YOU ADVISE ME?

Yes, our professional technical team will be happy to understand your needs and advise on your best options.

DO YOU STOCK SPARE PARTS?

Yes, we have a dedicated team for all spare and service part enquiries and we endeavour to keep parts for all our equipment in stock for next day delivery (48 hours for international customers).

WHAT HAPPENS IF MACHINE BREAKING DOWN OR REQUIRING HELP AND SUPPORT?

We have mobile engineers that are available for call outs. Alternatively support by phone or email is available 24/7.

Whar 's your after-sale service?

1, 12 months warranty from products departure. Enough spare parts and quick-wear parts sent together.

2, onsite installation, debugging, workers training. Make sure that your workers operate properly and know daily maintenance well.

3, Prompt reply in case of any problems.

What`s the service life of your machinery?

Usually 5-10 years under good maintenance.

How soon can you reply me?

In 1 working day, detailed quotation and program design will be offered.

What`s your delivery time?

5 days for single machines, 15 days for plants.

What are your payment terms?

T/T, L/C, Paypal, Credit card, Western union, Moneygram are all ok.

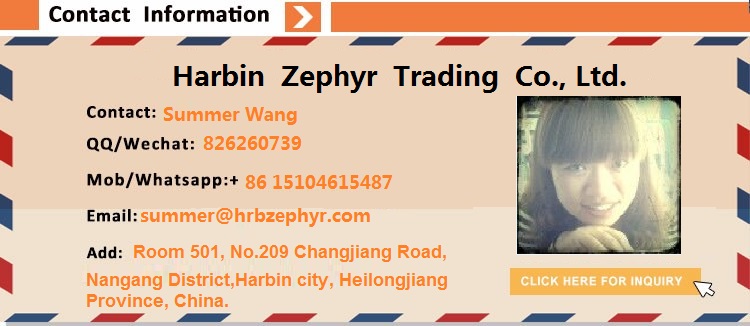

Contact Us

If interested in our products, please contact with us without hesitation.

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories