Search

- No link

|

|

QLB15 Midwest Asphalt Hot Drum Mix Plant

Product Description

QLB15 Midwest Asphalt Hot Drum Mix Plant Primary units structure adopt drying cyclinder, burner, positive double axle mixer. Regeneration units adopt drying cyclinder, unique fumace and reclaimed materials hoisting structure. Equipment ratio of mixture is raw ingredients 50% and used asphalt 50%. The used asphlat maxium ratio can reach 60%. It recycles and can get more benefits for user. Drum Asphalt Mixing Plant is designed with high efficiency, low consumption and low pollution. The asphalt plant adopts PLC control system that is easy to learn. DHB asphalt mixing plant mainly includes: cold aggregate supply system, burner, drying drum, mixing drum, dust removal equipment, asphalt supply system, electronic control system and so on.We also provide excavator,loader,bulldozer,dump truck etc construction machinery.

Features

1. Control System

The control room is safe and reliable, the appearance is beautiful, the lifting and transportation is convenient; the electric control adopts the desktop operation console, which can realize interlocking and single machine operation; the operation console is equipped with manual control operation device, and the operation is convenient and intuitive.

2.Raw material supply system

According to requirements of the project, the system can divide the aggregate into four different sizes, divide the large particles into medium-sized particles, and finally send the qualified materials to the drying drum through the conveyor belt.

3. Mixing host

The mixing host combines drying, heating and mixing. The aggregate forms an incomplete curtain in the drying zone and is preheated and moved forward; the curtain is completely formed in the heating zone and heated rapidly; the asphalt is sprayed in the mixing zone and is fully uniformly mixed with the aggregate.

4. Coal Combustion System

The coal that has passed through the high-efficiency coal crusher is processed into coal powder of less than 5 mm, which further accelerates the supply speed of suitable coal powder. The burner uses oil supply and blower to provide enough heat for the mixing station.

Technical Parameters of Asphalt Mixing Plant

Mobile Force Asphalt Mixing Plant | |||||||

Type | QLB-10 | QLB-15 | QLB-20 | QLB-30 | QLB-40 | QLB-60 | QLB-80 |

Capacity | 10t/h | 15t/h | 20t/h | 30t/h | 40t/h | 60t/h | 80t/h |

Power Diesel | 41.5kw | 54kw | 63.5kw | 104.5kw | 125kw | 157.5kw | 200kw |

Power Coal | 57.5kw | 75kw | 86.5kw | 127.5kw | 169kw | 205kw | 276kw |

Aggregate batcher | 2.3m3×3 | 2.3m3×3 | 5m3×3 | 5m3×3 | 5m3×4 | ||

Storage bin | 2t | 5t | 5t | 9t | 9t | 9t | 20t |

Product temperature | 120-180,adjustable | ||||||

Fuel consumption | Oil :5-7.5 kg/t | ||||||

Coal :13-15kg/t | |||||||

Optional | Coal miller , Wet filter, Bag House, Control room, Bitumen heating tank | ||||||

Package And Shipping

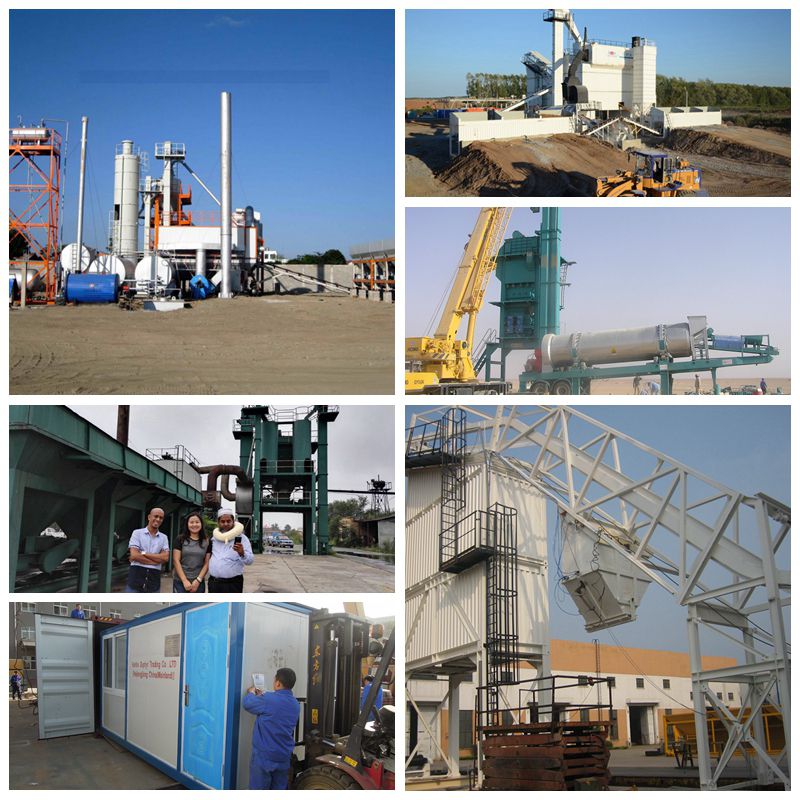

Our Successful Case

Our Service

--Installation and commissioning and acceptance

1). Our company will offer the buyer assistance of the equipment installation, commission ;

2). Each unit after installation will have returning visit by specialized departments;

--Technical material, warranty and free service

1). We will offer the buyer free training for their operator and maintenance worker, and also provide free technical advice services;

2). And company will organize technology training courses regularly, and give free training the buyer's operator.

--Spare parts supply services in time

Our company offers the original, authentic, quality spare parts for the machine maintenance accessories.

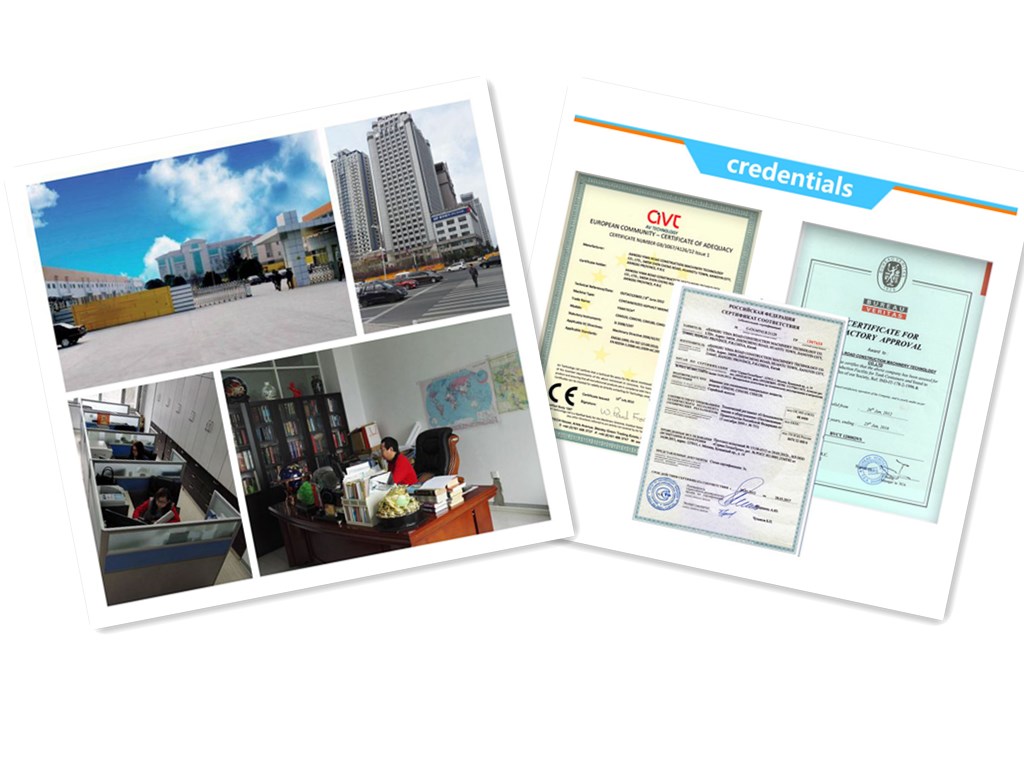

Company information

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crushing and screening production line and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have reveived the ISO9001,CE,SGS etc certificates.Our equipment has exported to35 countries,including:Russia,India,

Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant or constructions machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

Contact information

FAQ

Q:How many days are used for installation of one set asphalt plant?

A:Around 15-20 days, according to local situation.

Q:Do you provide overseas Installation and training service?

A:Yes, we can send experienced engineers to your country, guide installation and commissioning and train your workers how to operate the plant.

Q:How long is the delivery time?

A:30-40 days, according to different configuration.

Q:How to go to your actory ?

A:Our city has airport. If by air, you can fly from Guangzhou/Beijing/Shanghai 1.5 hours.

Q:Can I visit your factory?

A:Of course. We warmly welcome you to visit our factory. And we can arrange everything ready before your arrival.

Q:How long is the warranty of your asphalt plant?

A:normally 12 months

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories