Search

- No link

|

|

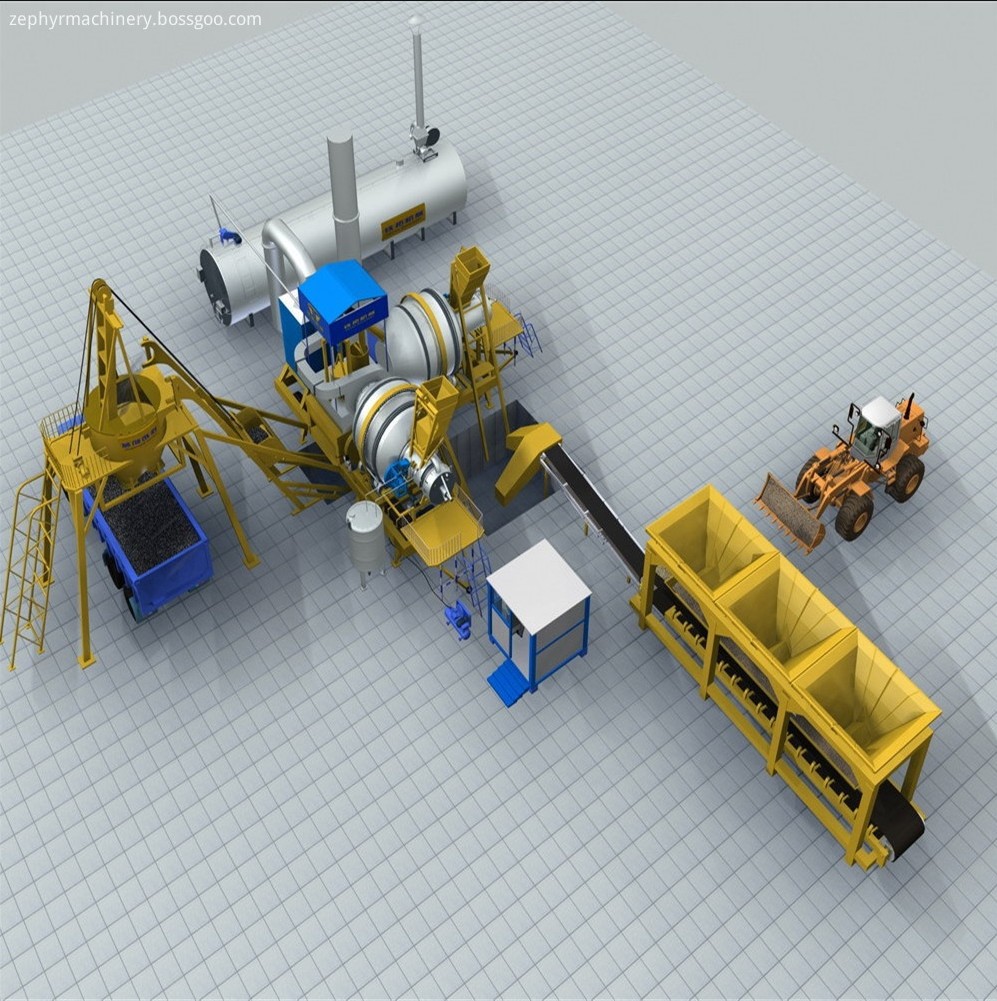

Portable Drum Asphalt Mixing Plant

Product Description

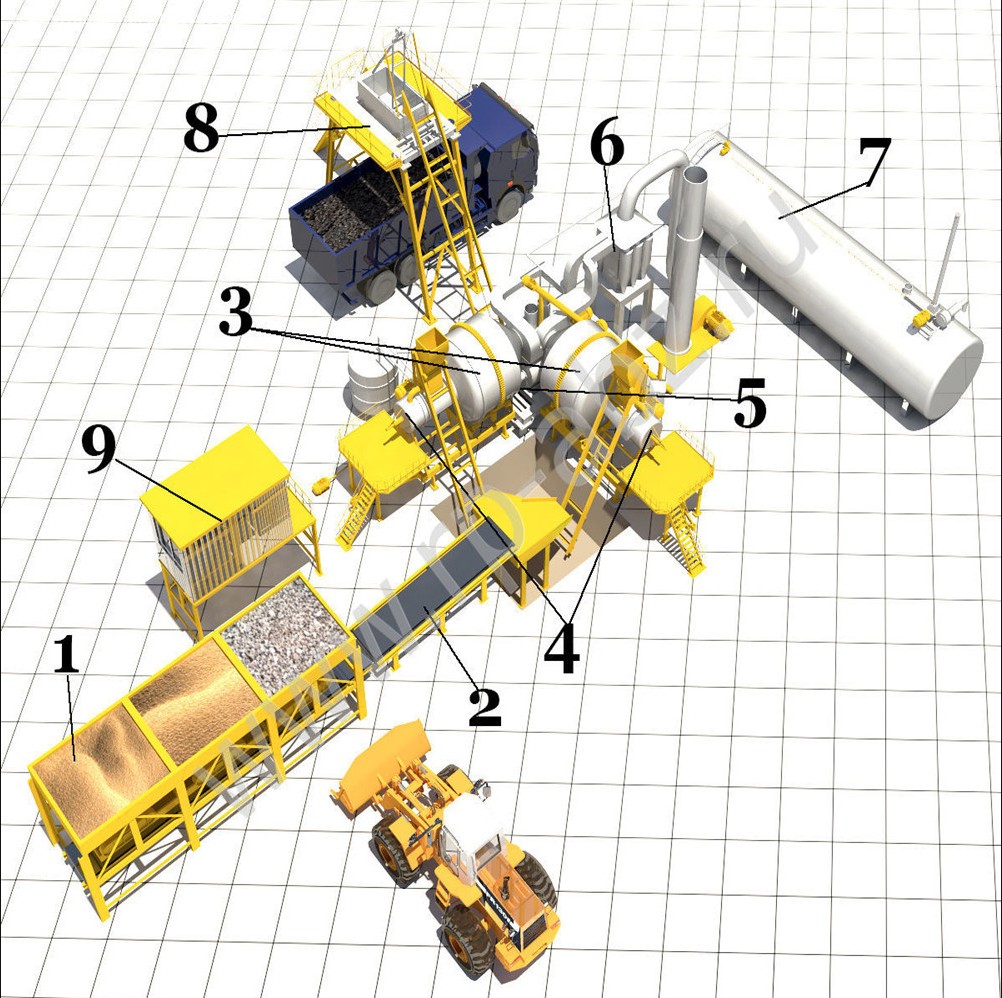

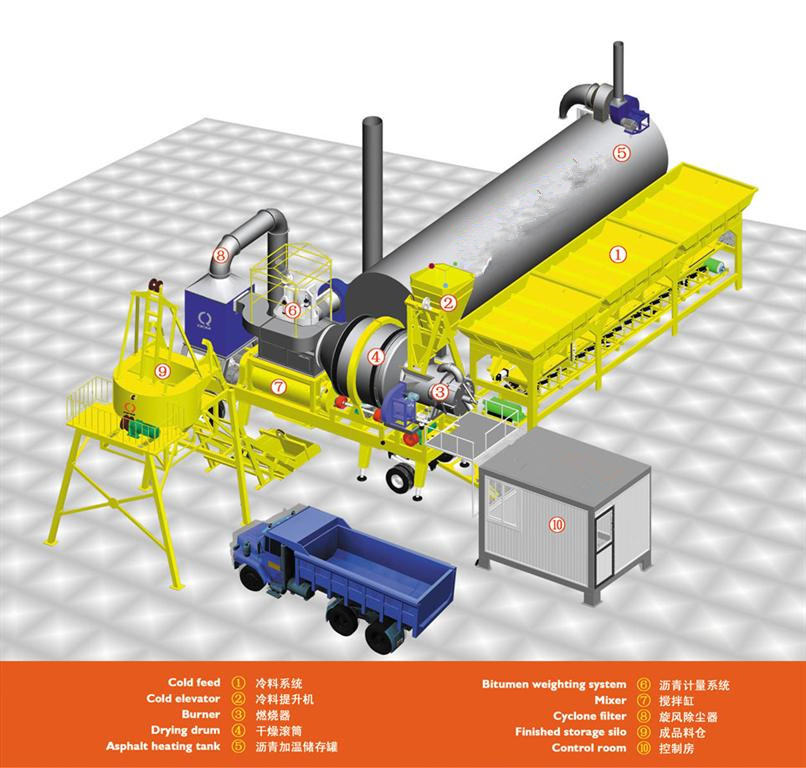

QLB20 Asphalt plant is a kind of Mobile compulsory asphalt mixing plant, it is suitable for small and medium project for producing, modifing, and coloring asphalt. and the whole processing can be measured by weighing system, so the finished asphalt quality is higher compared with drum asphat mixing plant.Mobile asphalt batching plant using twin-horizontal shafts force mixer saves stirring time and makes bitumen wrapping in a high degree. It blade, vane and mixing arms are made of special wear-resisting material and they can work longer. Material-added gate with double air cylinder is in turning form which saves time and increase the sealing. It consists of dryer drum, burner, central venting, forced mixer, finished silo and three bin feeder for cold aggregates.

Features

1.Cold Aggregate Supply System

Bin volume and number is customizable, Separated structure design significantly reduces dimensions for shipping and ensures a high capacity.

Two independent cold feeders and modular design, transport expediently.

Seamless ring belt, high reliability and long life.

Frequency convertor controlled SIEMENS motor, infinite variable speed adjustment, more accurate and energy saving.

2.Drying Drum

SIEMENS motors, hard-teeth reduction gear, friction driving, drum rotating stably.

Optimized lift blade design, make sure heating equably and high energy using ratio.

With 50mm insulating layer and stainless steel skin, avoid heat be lost.

3.Burner

Italy EBICO oil burner imported with original packing, high burning efficiency, diesel, diesel/heavy oil dual purpose or gas as fuel is optional.

With automatic flame failure protection devices for emergency.

4.Dust Collection System

Two level dust collection system (volute casing collector + bag house collector), with high and low temperature protection device for the system security.

Bag house collector using USA Dupont NEMEX bags, heat resisting and long life.

5.Mixing Tower

Both aggregate and filler elevators are equipped with a double ring chain bucket, which is more reliable and convenient for maintenance.

Twin shaft compulsory asphalt concrete mixer (the mixing arm is cross arranged with changeable gridded mixing blade), high mixing efficiency and long life.

SIEMENS motors with hard-teeth reduction gear, most stably and high performance.

Bitumen is sprayed into mixer through a special designed spray bar with high pressure to reduce feeding time and increase mixing uniformity.

Totally enclosed type circular vibration screen, modular design, vibration motor driving, low maintenance and long life.

Double layer much bigger hot aggregate storage hopper can effectively guarantee the continuity of the supply of hot aggregate; with 50mm insulating layer to avoid heat be lost.

6.Bitumen Supply System

Volume and number of bitumen tanks is customizable according to user requirement.

Heat transfer oil heating type, heating equably.

7.Filler Supply System

The standard stacked filler silo design is more convenient for connection with main tower and requires less space for installation.

Volume and number of filler silos is customizable.

8.Control System

Automatic/manual control system, with fault self-diagnosis process, operate easily and safely.

SIEMENS PLC electrical control system, reliability is high.

Fully graphic Multilanguage control interface is easy and convenient for different operators.

Technical Parameters of Portable Asphalt Mixing Plant

Model | QLB20 |

Capacity | 18--22 t/hr |

Burner | diesel / gas |

Fuel consumption | 5-7.5kg/t |

Weighing sensor | TSC-1500(TOLEDO) |

Asphalt Mixer | ASM800/500 twin-shaft asphalt mixer;20t/hr |

Operation system | Manual/Auto operation system |

Control system | PLC control system, formula input |

Dust collection system | Level one filter:cyclone filter |

Aggregate Storage Bins | Storage Bins: 5 m³X3 , accumulative scale |

Weighing Accuracy | Aggregate ≤1500kg ±3% |

Filler ≤80kg ±2% | |

Bitumen ≤80kg ±2% | |

Aggregate size | ≤40mm |

Hot Asphalt temperature | 130~170 °C,adjustable |

Total Installation Power | ≈91kW (diesel burner) |

Electrical Design | 220/380V-50Hz |

Package&Shipping

Our Service

Company Information

Harbin Zephyr Trading Co.,Ltd locates in the north of China, province Heilongjiang,city Harbin.This is an international trading company mainly exports large road machinery such as:asphalt mixing plant,concrete mixing plant,crushing and screening production line and Ex cavator ,Loader,Bulldozer,Dump truck and so on...

As one of the first professional supplier of asphalt mixing plant and concrete mixing plant in China,we have always given attention to maintaining our higher level quality control and service , and we have reveived the ISO9001,CE,SGS etc certificates.Our equipment has exported to 35 countries,including:Russia,India,Bangladesh,Ghana etc.

If you have any inquiry about the concrete mixing plant or constructions machinery,please fell free to contact us,We are always warmly welcome you to come and look forward to our meeting!

FAQ

Q:How is the quality of your products?

A:Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection

Q: How about the price?

A:We are factory and be able to give you the lowest price than market one, and we have a policy that [ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity".

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Q: Can you test our samples?

A: Yes. You can send your samples to us for test and analysis.

Q:Service and Payment Terms?

A: We usually accept T/T, L/C; T/T: 30% in advance as down payment, the balance before delivery; We take pictures of finished products before delivery.

Contact Us

If you have any idea, pls contact us!

We can provide the customized service for you!

Instant Messaging

Instant Messaging Video Call

Video Call

All categories

All categories