Harbin AVIC Kegong Bearing Co., Ltd.

Design and development of bearing products and accessories, technology transfer, technical consulting services; sales: bearings and accessories, special equipment and accessories for bearing production, metal materials, wear-resistant materials, special instruments for bearing testing, machine tools and accessories, agricultural machinery and accessories , Construction machinery equipment and accessories, mining machinery equipment and accessories, water pump motors and accessories, electromechanical products, plastic products, rubber products, instrumentation, laboratory equipment, hardware, auto parts, elevator accessories, amusement facilities and accessories, lubricants (finalized Packaging), building materials, labor insurance supplies, cultural goods, sporting goods (excluding crossbows); computer software and hardware technology development, technical consultation, technology transfer; exhibition services; conference services; etiquette services; mechanical equipment operating l

Search

|

|

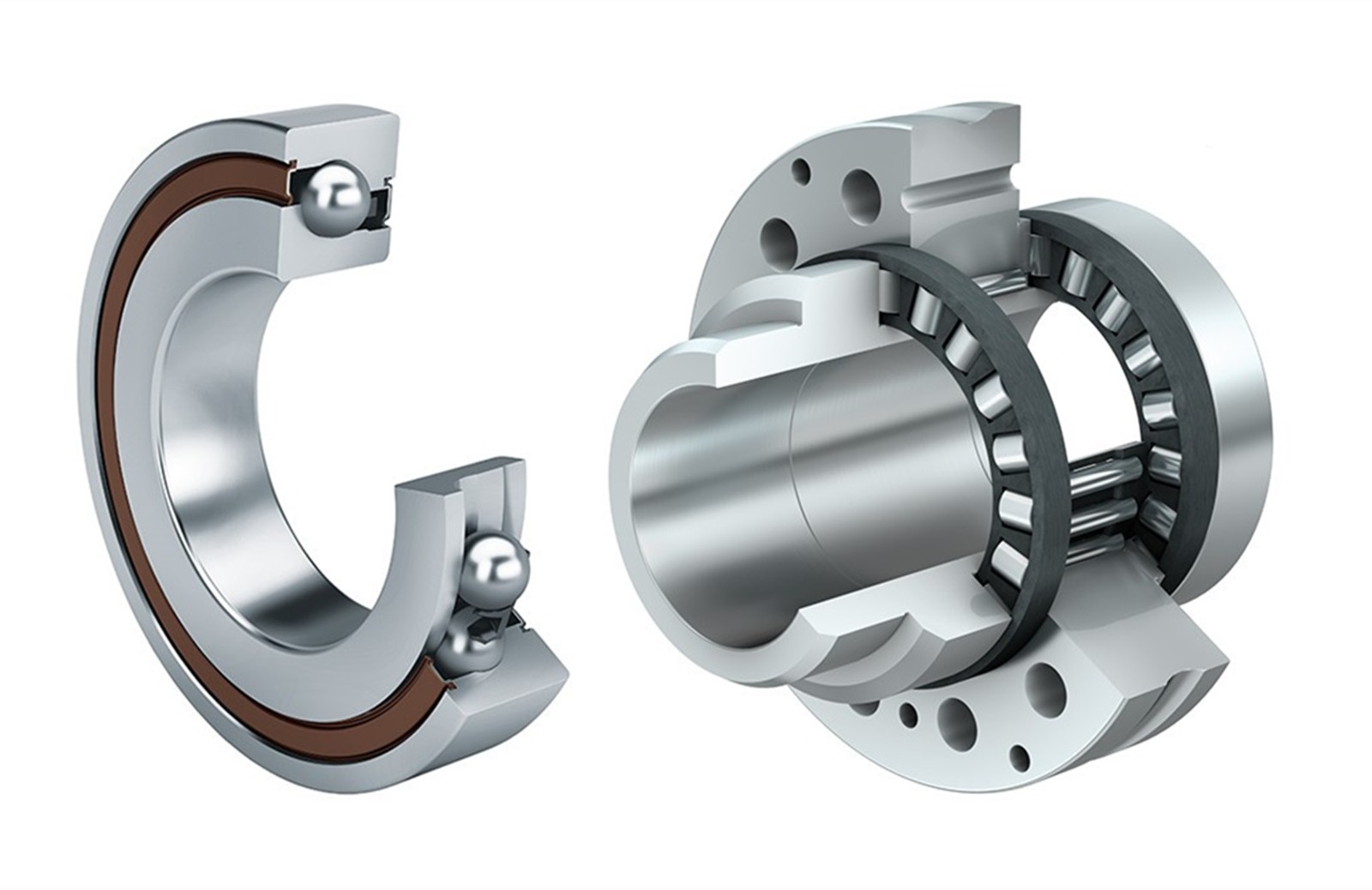

Introduction of maintenance-free bearings

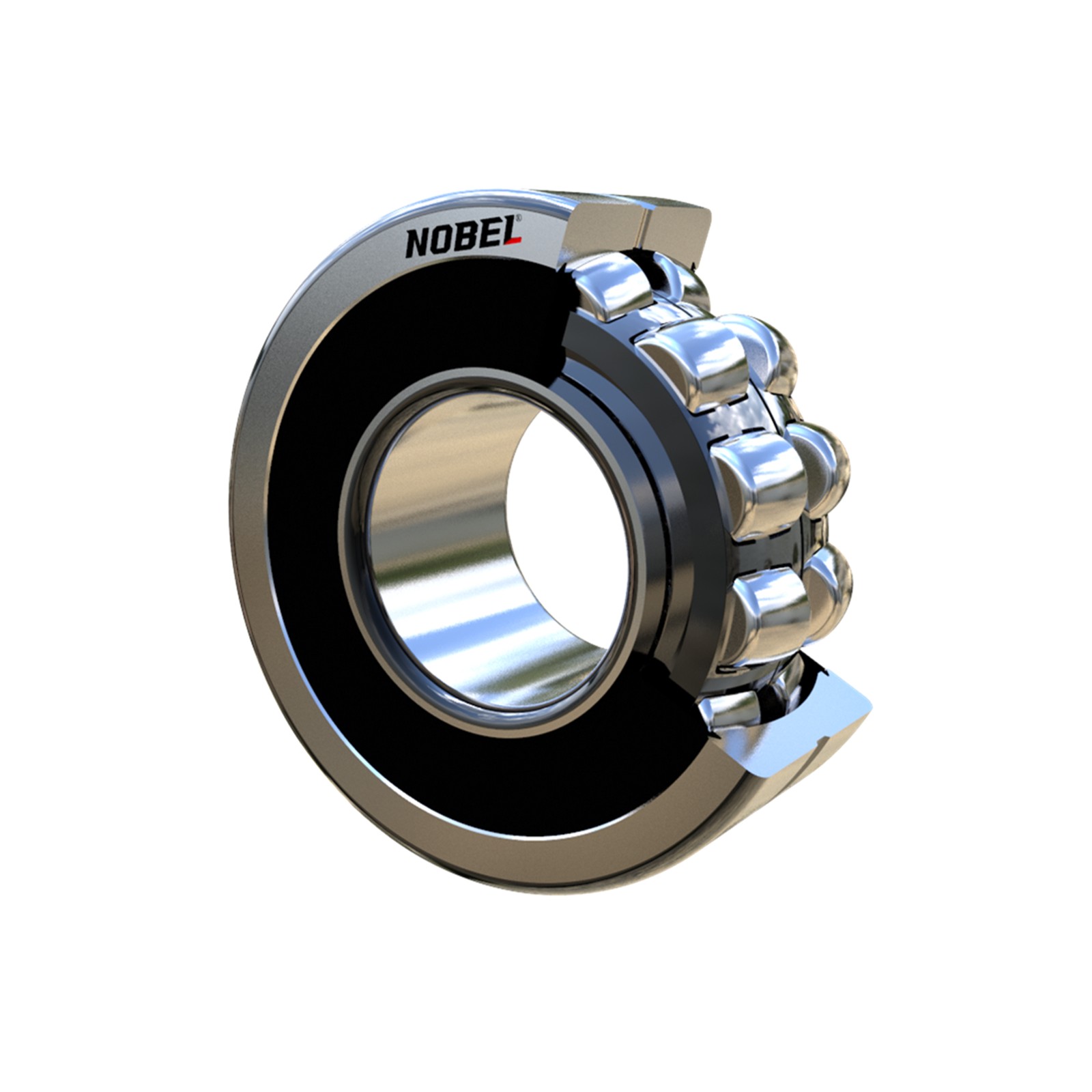

Maintenance-free bearings, maintenance-free bearings in high-strength fatigue tests refer to rolling bearings that can work stably for a long time from maintenance to failure, and are an advanced rolling bearing technology. Reliable and durable excellent performance.

The technical principle of the maintenance-free bearing is to optimize the geometry and surface finish of the bearing raceway, the redesigned cage, the use of high-performance bearing steel and a unique heat treatment process, and improve the accuracy of the steel ball. Reduced grease consumption; the optimized sealing structure is easier to store grease and lubricating oil to the channel, and cooperate with the full-life grease filling to provide longer-lasting lubrication for rotation. A number of process improvements and applications have achieved tremendous improvements in bearing performance, eliminating the need for regular maintenance during the bearing life cycle.

Compared with traditional standard bearings, maintenance-free bearings have the following advantages: 1. Oil-free, long life, can greatly reduce the frequency of bearing replacement and reduce waste generation; 2. The use of special maintenance-free technology, no need to oil the bearing , The device will not cause pollution due to continuous fueling, and can maintain a clean working environment; 3. Compared with standard bearings, maintenance-free bearings have a longer service life and can reduce CO2 emissions by 79.1%. Reduce the environmental load by extending the service life of the bearing; 4. LongevityDedicated use can reduce the operating cost of the enterprise. Even if the initial cost of procurement is higher than that of standard bearings, it can significantly reduce the overall cost.

In the world, there are more and more demanding requirements on energy utilization, efficiency improvement and environmental protection. Bearing technology tends to be more efficient, energy-saving and environmentally friendly. The trend is high speed, convenience, high precision and unitization. The era of high performance resistant to special environments and maintenance-free has arrived.

Instant Messaging

Instant Messaging Video Call

Video Call